Metal Ceilings

Metal ceilings are usually specified in modern buildings for many valuable reasons. It is considered as high performance ceiling due to the increased life span and durability. The high recyclable content also makes it one of the most valuable ceiling solutions in the new building code.

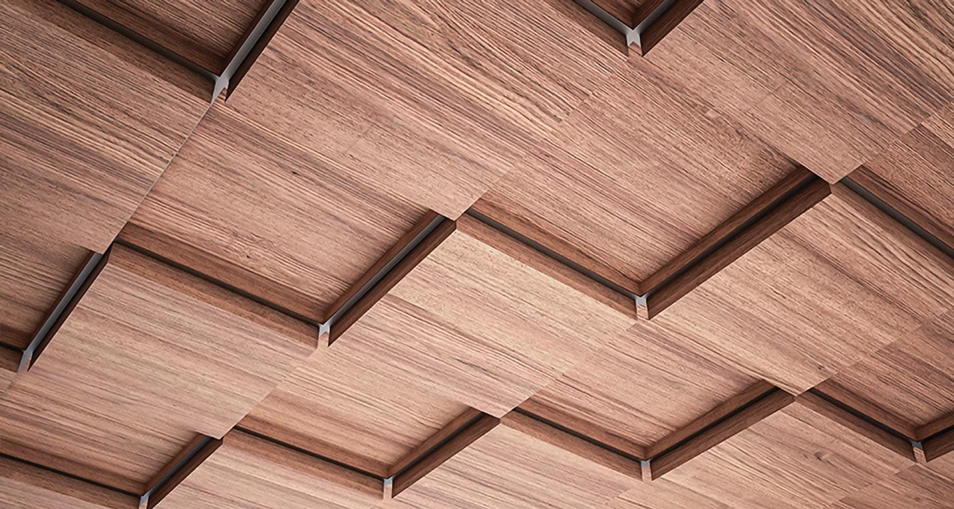

The metal ceiling can be produced in different shapes, colors and patterns from plain to perforated, square, rectangular, trapezoidal, wave and curve.

Marconi Metal Ceiling range varies from standard products to baffle shaped, beam grid, S-like shaped, Mesh patterned, open grids cells design, and strip and tile designs. We are able to provide a variety of solutions up to any custom made designs specified by the architects and designers.

Our metal ceiling solutions are manufactured from several raw material including Aluminum alloy 3000 and 5000 series and hot dipped galvanized steel.

Acoustic Performance:

- Tested and compliant for noise reduction, sound absorption and sound attenuation.

- Acoustic Black Fleece only: Maximum

- NRC = 0.80 as per ASTM C423. ONCW = 46 as per BS EN 20140·9.

- Acoustic Black Fleece with Rockwool as per ASTM C612 has a maximum NRC=0.98.

- Maximum CAC achieved: 46 db.

In order to improve interior sound control, perforation pattern with an open area of 16% to 22% is required. These patterns are framed with a solid border of 10mm in order to ensure maximum flatness and product stability. As a standard feature, perforated tiles are supplied with a sound absorbing nonwoven acoustic felt for enhanced acoustical properties, tested in accordance to AS TM C423a. Rockwool insulation pads of 25-50mm thick, 40-110kg/m3 density can be applied.

Anti-Bacterial:

Stove enameled finish with anti-bacterial properties that prohibits bacterial growth as per JIS Z2801:2000

Fire Performance:

Non-Combustible as per BS 476: Part 6. Class 1 Surface Spread of Flame as per BS 476 Part 7. Black Fleece is Non-Flammable Class A as per ASTM E84.

Finishes:

The panels are finished with an electro-statically polyester powder coat (thickness of 60-120 microns) and are available in standard color RAL9010. Other colors (RAL, NCS, made to match) are available as per architect’s specifications. These panels are salt spray tested for 1000 hours corrosion protection, as per AS TM B 117-73, and Anti- Bacterial finish, as per JIS 2801:2000, is also available upon request.

Fire Classification:

Surface spread of flame class 1 as per BS 476 : part 7 1997. Non-combustible material tested in accordance to BS 476 : Part 4: 1970. Class O material surface of composite products as per building regulations 1991. Fire propagation tested as per BS 476 : Part 6 1989. Additionally fire rated F90 system was tested for 115 minutes fire resistance in accordance to BS 476 : Part 23:1987, Clause 5.

Architectural and Finishing Solutions

- Mechanical Cladding Fixation (Stangle)

- Waste Management (Garbage & Linen Chutes)

- Drywall & Ceiling Profiles

- Metal Ceiling Grid System

- Architectural Expansion Joints

- Tile Movement Joints

- Wall Profiles

- Stair Nosing

- Entrance Matting System

- Phenolic Partition Systems

- Raised Access Floor System

- Pedestal & Grid Raised Floor

- Handrails

- Impact Protection Systems

- Metal Ceilings

- Acoustical & Decorative Ceilings

- Metal Doors

- Gyproc Systems & Solutions

- Partition Systems

- G-Board Systems

- Gypsum Boards & Accessories

- Cement Boards & Accessories

- Insulation Systems

- Heavy Impact Protection Systems