Bitumen Modified Moisture Curing Polyurethane Membranes

Mapegrout T60 ME is a single component, thixotropic cement-based mortar formulated to compensate for hygrometric shrinkage. Mapegrout T60ME is composed of pre-blended hydraulic binders, synthetic polyacrylonitriVBVle fibers, organic corrosion inhibitors, selected aggregates and special water-retaining additives. Under extreme climatic conditions and/or where correct or adepuate curing cannot be maintained, the addition of Mapecure SRA is hughly recommended in order to ensure the required performance criteria are attained. Mapecure SBA is considered a technologically advanced additive system thathas the capabilityof slowing down the evaporation rate of the mixing water thereby promoting the efficiency of the hydration process. The addition of Mapecure SRA in proportions of up to 0.25% by weight has the abilityto reduce drying shrinkage between20% and 50%. Where concrete repairs are required, particularly as a result of chloride-induced corrosion of the reinforcing steel. the incorporation of Mapeshield I internal galvanic protection anodes. should be considered or Mapeshield E. external galvanic protection sheet which can be used to protect both repaired and unrepaired areas. Please consult the relevant technical data sheet in order to correctly select the type, size and spacing of the anodes system. Mapegrout T60 ME meets the requirements defined by EN 1504-9 (“Products and systems for the protection and repair of concrete structures — Definitions, requirements, quality control and evaluation of conformity — General principles for the use of products and systems") and the minimum requirements claimed by EN 1504-3 ("Structural and non structural repair") for stmctural mortars of class R4.

Where to Use

Repairs to both new and old conrete structures or reinforced concete elements subject to aggressive atmospheric conditions including chloride and sulphate attack.

Some Application Examples

- - Reinstatement of cover to reinforcing steel and re-establishing structural integrity.

- - Repairs and reinstatement of manholes, sewerage structures and other utilities.

- - Repairs to industrial facilities including oil and gas, marins and other structures operating under extreme working environments.

- - Water retaining and excluding structures, tunnels and canal linings.

- - Filling of rigid joints (between base and column, cracks in floors, joints between walls, ect.).

- - Repair of precast concrete elements.

Application Procedures

- Preparing the substrate

- - Remove degraded andfor loose concrete until a souid and solid sibstrate is achieved.

- - Where necessary clean the concrete and reinforcing steel by sweep blasting or otherapproved mechanical methods to remove all dirt, any corrosion prochcts, cement laitance, geese, oil, any previous coatings and other deleterious elements.

- - Any previous repairs that are no longer thoroughlybonded must also be removed.

- - Pre-soakthe substrate with clean. potable grade water to obtain a satuated surface dry {SSDJ condition.

Key Benefits Summary

- • Highly flexible - over 900% elongation.

- • No seams or laps.

- • Generally no priming required.

- • Single layer application possible.

- • Ready for immediate use (no mixing required).

- • Accomodates crack movement from 0 to 1.6mm when fully cured at 1.3mm thickness.

- • Withstands hydrostatic pressure of up to 4m head of water while bridging a crack of 1.5mm width.

- • Over 15 years proven performance.

- • Available in self-levelling (H) grade or rollable grade (R) for easy application.

Packaging

- • 25 KG Bags

Standards

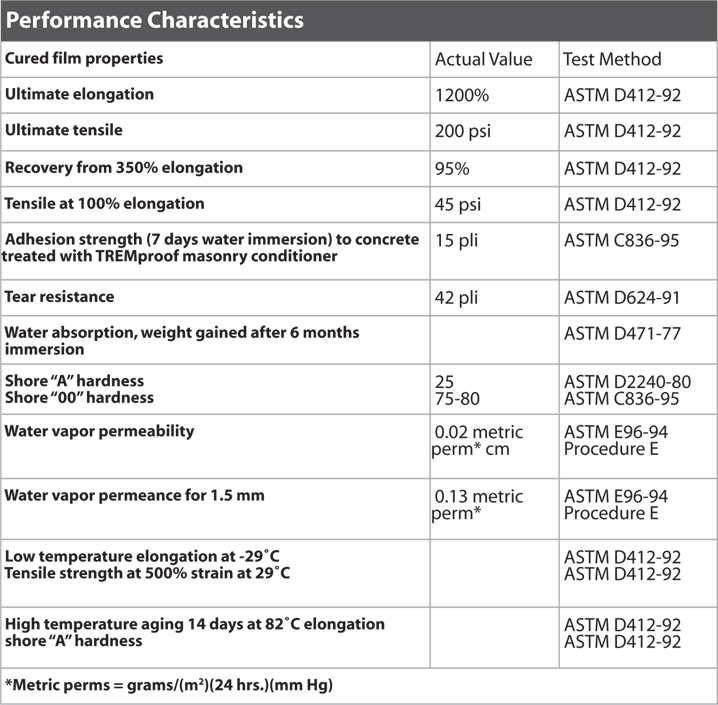

- • ASTM C836-84

Description

- TREMproof® 60 is a single component, bitumen modified, moisture curing polyurethane fluid applied waterproofing membrane.

Usage / Porpouse

- Waterproofing of:

- • Roofs, Tunnels, Terraces, Balconies Plaza Decks

- • Planter Boxes

- • Retaining walls

- • Fountains and pools

Limitation

- • Applications where the applied membrane will not be covered over and where the membrane will be subjected to traffic.

- • Lightweight concrete substrates without prior approval in writing from Tremco.

- • Use with thin bed tile adhesives, with out prior consultation with Tremco.

- • Applications where the applied membrane will be subjected to UV exposure.