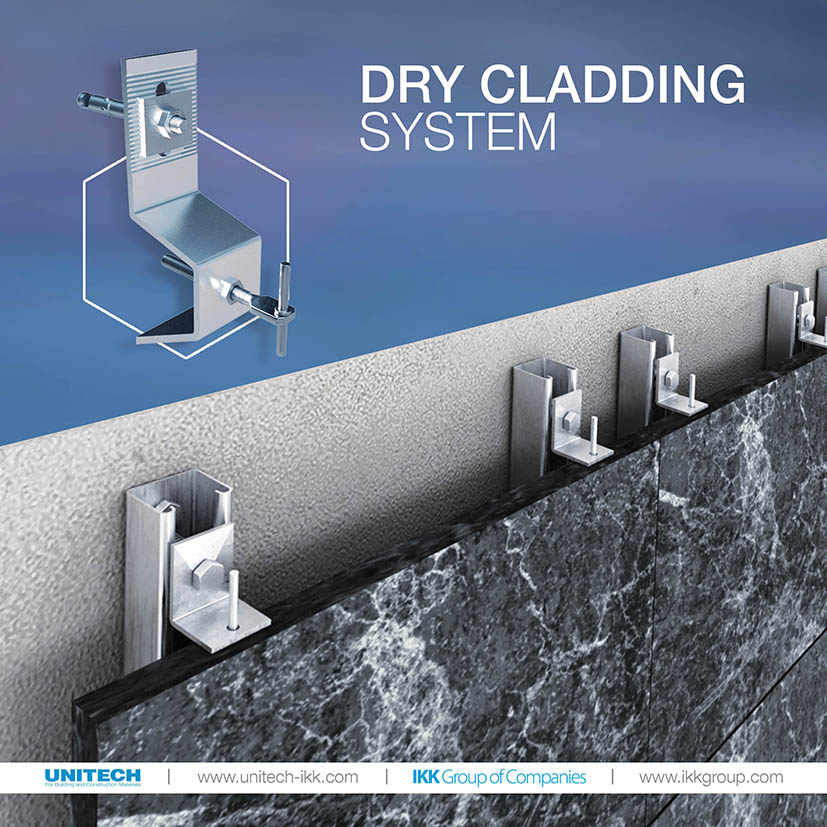

Dry Stone Mechanical Cladding Fixation System

Dry Stone Mechanical Cladding fixation systems is defined as the best and safest methods for the installation of all kinds of masonry. Unlike the traditional wet cladding installation, the dry cladding systems maintains a high level of accuracy when installing the stones and can be easily adjusted to ensure perfect appearance of the building and at the same time, preserves the color of the stone by avoiding direct contact with the substrate.

Dry Stone Mechanical Cladding System components vary depending on several factors such as:

- 1- Stone Weight

- 2- Cavity Size

- 3- Building Architectural design

- 4- Concrete Slabs

The system can include metal framing, which consists mainly of steel C-Channels of various finishes, heavy duty anchors, steel brackets and bolts. Some stone cladding having a relatively low-weight panels can be mounted using aluminum panels, but the most common system used in dry stone mechanical cladding is made up of steel, and specifically stainless steel which can withstand all weather conditions, and is among the best materials against corrosion.

The best stainless-steel grades which are immune to corrosion are SS316 TI and SS316 L, while in a relatively low humid areas SS304 can be used safely and efficiently for a complete mechanical cladding system components.

But, what makes such system beneficial and widely used?

The system has a set of benefits which makes competency with dry cladding installation out of question, making it essential for stone cladding installation worldwide

- • Safety: The possibility of the fall of the stone over the years is unviable.

- • Easy Movement: This method of fixing mechanical stone cladding allows for the contraction and expansion of stone in the extremities of weather, i.e. in hot and cold areas where such kind of movements are common.

- • Thermal Barrier: The process of dry stone mechanical cladding creates a cavity of 30 to 50 millimeters in between the stone lining and the back wall. This provides air cushioning performing as a thermal barrier which prevents from extreme heating or cooling of concrete wall.

- • Time Saving: Mechanical fixing stone cladding is preferred over other methods as it saves installation time. It requires low maintenance cost.

- • Excellent Appearance: The stone used in the mechanical cladding looks aesthetically great and remains in the best condition and appearance over the years, thus, maintain a perfect condition and appearance of the building over the years.

For more information: